In this series of articles, I will be describing in detail how to build this 24″ Ribbon and Bow Shelf. This shelf can be built out of any suitable wood that is capable of being stained or painted. The shelf that is pictured to the left was made from 3/4″ spruce but red oak, poplar, or mahogany would work just as well depending on your budget. So let’s get to building this shelf right away.

The Back Plate

The back plate for this shelf is cut from a piece of 1″ x 8″ x 24″ material. In lumber terms, a 1″ x 8″ board is 3/4″ thick and 7-1/2″ wide. The original rough cut board from the saw mill is 1″ x 8″ and then planed down to the finished dimensions for a smooth finish.

To create the patterns for this shelf, we will be using poster board. Poster board can be purchased anywhere school supplies are sold and usually comes in sheets of 22″ x 28″. The patterns for all the parts of this shelf can be cut from a single sheet of poster board. Poster board usually comes with one glossy side and one matte side. When drawing on the poster board, draw on the matte side because the glossy side won’t accept pencil marks very easily.

To start the layout for the back plate, take a piece of poster board and cut it so that it measures 8″ wide, and 24″ long. Now fold this piece in half so it measures 8″ x 12″ and lay it down on a flat surface so we can do some measurements and draw some straight lines. First mark one of the 12″ sides of the pattern as the top and place the pattern so the top is oriented at the top. Using the illustration above, start at the fold of the poster board and measure down from the top 7-1/2″ down along the fold and place a mark.

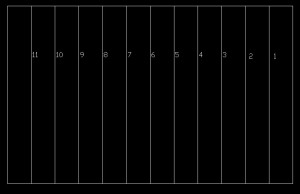

Now measure 1″ from the fold and using a framing square mark a line parallel with the fold from the top to the bottom. Now draw ten more lines from the top of the pattern to the bottom spaced 1″ apart all the way to 1″ from edge opposite the fold. Starting at the fold, number each of these line 1 through 11. When finished, you will have a pattern folded in half with 11 parallel lines running from top to bottom 1″ apart on the face of the pattern as illustrated below.

At the fold, measure down from the top 7-1/2″ and place a mark. Now go to each line from the fold to the opposite edge and mark the following measurements from the top. #1…7-15/32″, #2…7-11/32″, #3…7-5/32″, #4…6-7/8″, #5….6-17/32″, #6…6-5/32″, #7…6″, #8…6-1/16″, #9…6-3/8″, #10…6-25/32″, #11…6″. Now at the edge opposite the fold, measure down from the top 6″ and place a mark.

Now what we are going to do is simply connect the dots along the bottom of the pattern to create the contour of the bottom of the back plate. The easiest way to do this is to take your pencil and smoothly form a slight curve between the points so that your pattern looks like the back plate illustration above. Craft stores sell a flexible drawing tool that can be curved to the shape of the dots if you don’t feel comfortable drawing it freehand. If you have one of the tools, just lay it out on the pattern and bend it’s shape to match the points along the bottom of the pattern and trace along the tool from point to point.

When your pattern is drawn, take eight pieces of scotch tape and tape the two layers of the pattern together using four pieces along the top and four along the bottom of the pattern. It is essential that you not let the two layers of the pattern slip when cutting out the pattern. Now take a pair of scissors and cut through both layers of the folded pattern along the line that you just drew.

When your pattern is cut completely, take a small paring knife and cut the tape along the top and bottom of the pattern. Now unfold the pattern and you have a complete pattern for the back plate that is 24″ long and is a perfect mirror image of itself.

When you are satisfied with your pattern, with a miter saw, cut a piece of 1″ x 8″ to exactly 24″ long. Now place the pattern on top of the piece of wood. Next take some blue painter’s tape or masking tape and tape the pattern along the top and both ends of the board. Do not put tape along the bottom edge as it will get in the way of tracing the pattern onto the board. Now draw along the bottom edge of the pattern while holding the pattern down against the board with your other hand. Take it slow and easy and don’t push too hard against the pattern which will cause it to slip.

Once you have traced the pattern onto your board, you are ready to cut it out. The only cut that is necessary is along the bottom edge if the board is square on both ends. A jig saw, or somtimes called a sabre saw, is the easiest saw to use to make this cut. However, before you start the cut, we will drill some holes along the bottom of the board to make turning the jig saw easier at the turning points. Take your drill and place a 3/8″ drill bit in the chuck. Now measure down from the point at the bottom edge where line #10 intersects the bottom of the pattern 3/16″ and place a mark. This will place the center of the hole just far enough below the pattern mark so that the edge of the hole intersects the edge of the pattern at that point. Now drill a hole at this point, making sure to hold the drill perpendicular to the surface of the board so the hole goes straight through. Do this at the same point on the other end of the board where line #10 intersects the edge of the pattern.

When the holes are drilled, take your jig saw and start cutting the board on either end being very careful to keep the blade just on the outside edge of the line. If you have a good quality belt sander, you can even leave about 1/16″ of material outside the line and then sand to the line for a nice clean edge. When you reach the first hole you drilled, you can very easily turn the jig saw in this hole and keep cutting along the line. Without this hole, making this turn would be very difficult. Do the same thing at the last hole and continue cutting all the way to the other end.

When the back plate is completely cut out, use your belt sander and clean up the cut making sure you remove all the saw marks from the edge. It should not be necessary to sand the top edge since this is a factory edge. Depending on how sharp your miter saw blade is, you may not even need to sand the end cuts until after you have routed the edges.

The last operation to the back plate is to route the bottom edge and the two ends. Do not route the top edge. Place a 1/2″ round-over router bit in your router and set the bit so that only the curved portion of the bit is below the router surface. All we want to do here is round over the edge, not form an ogee. Now route along the bottom edge and the two ends of the back plate.

When the routing is done, take your random orbital sander and sand the entire back plate so it has a nice smooth feel. Wipe the dust off of the back plate and you are ready to move to the next part of the shelf.

In the next article, we will be cutting out the two support braces for the shelf. See you in the next article. As always, thanks for stopping by.